All Regarding Stretch Wrap Machine Repair Service: Necessary Tips for Keeping Your Tools

Maintaining a stretch Wrap Machine is necessary for ensuring its effectiveness and durability. Routine assessments and attending to usual issues can prevent costly downtime. Comprehending the Machine's elements and applying routine upkeep techniques are key actions. Several operators forget the nuances of troubleshooting and proper training. What are the ideal practices for maintaining your tools in top shape? Discovering these critical elements can lead to more trustworthy operations and less unforeseen failings.

Recognizing the Components of Stretch Wrap Machines

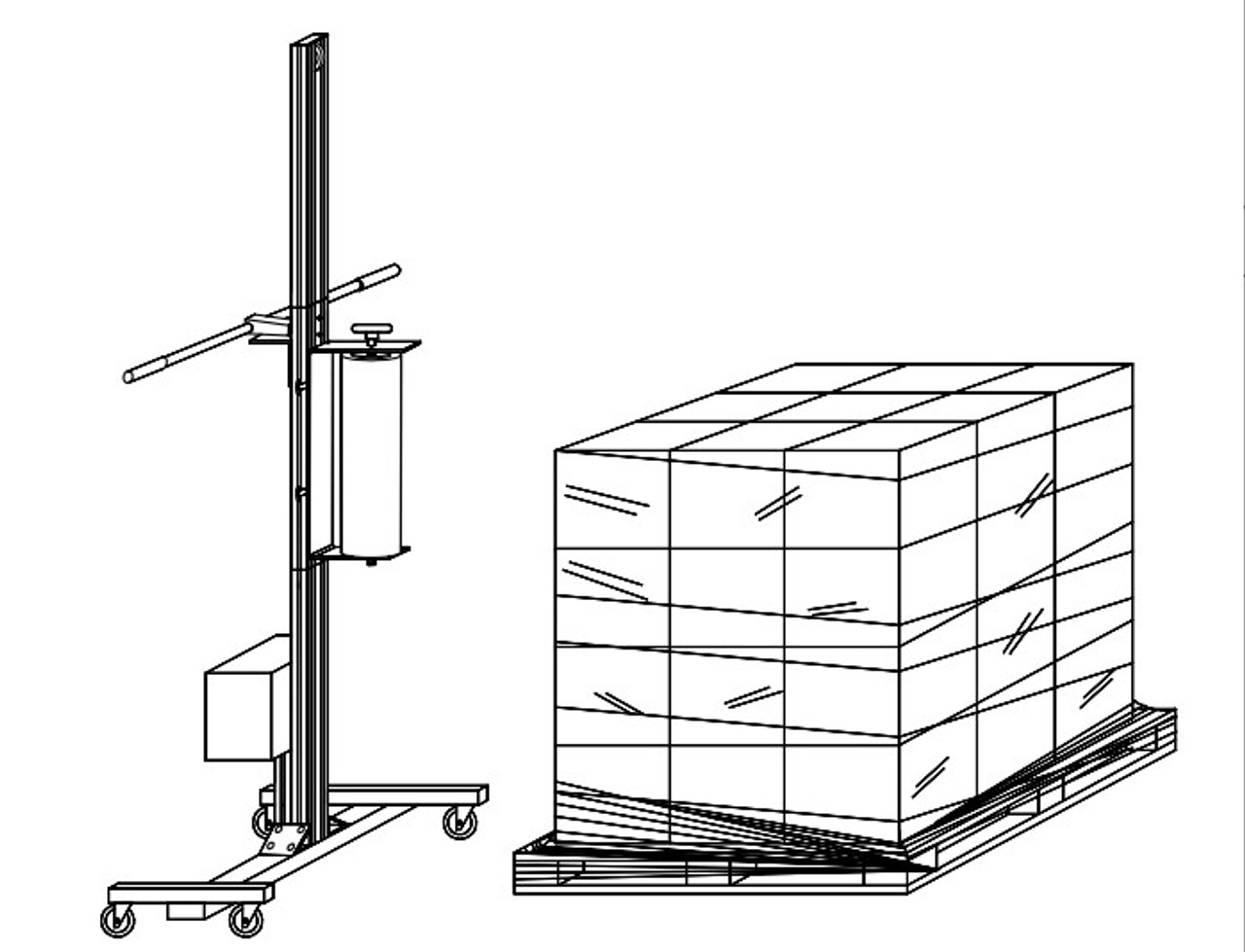

Stretch Wrap makers are crucial devices in product packaging procedures, designed to secure products on pallets for storage and transportation. Comprehending their elements is basic for effective maintenance and operation. Secret elements include the film carriage, which dispenses the stretch movie, and the turntable or arm that revolves the load for also covering. The control panel permits operators to change setups such as tension and speed, making certain ideal covering problems. Furthermore, the power supply is important for the Machine's operation, while the frame gives structural integrity. Sensing units are likewise integrated to find lots size and change covering appropriately. Each element plays a substantial role in the general efficiency of the Machine. Regular experience with these components can help operators in troubleshooting and regular upkeep, avoiding downtime and making sure constant performance in the packaging process. Recognizing these parts is the very first step to making sure longevity and reliability in stretch Wrap equipments.

Typical Concerns and Their Solutions

In any packaging operation, concerns with stretch Wrap makers can occur despite a solid understanding of their components. One usual trouble is inconsistent covering stress, which can lead to under- or over-wrapped loads. Readjusting the stress setups or inspecting the movie feed can often fix this problem. Another frequent problem is film tearing, commonly triggered by inadequate quality material or wrong handling. Switching to higher-quality film and ensuring appropriate filling techniques can assist stop this. In addition, Machine jams may happen as a result of particles or misalignment. Consistently checking for obstructions and making certain that parts are correctly lined up can alleviate this threat. Electrical failings can disrupt procedures; inspecting connections and replacing faulty parts is important. Dealing with these usual concerns quickly can improve Machine performance and extend devices life-span, eventually ensuring effective product packaging processes.

Routine Maintenance Practices

Routine maintenance methods are necessary for the durability and performance of stretch Wrap machines. An everyday evaluation list, a well-defined lubrication schedule, and clear part replacement guidelines are important parts of this upkeep routine. Executing these methods can aid stop unanticipated breakdowns and assure smooth procedure.

Daily Evaluation Checklist

Regular inspections of the stretch Wrap Machine are important for ensuring peak performance and durability. A daily examination checklist must consist of vital elements to keep track of. Operators need to check the film tension and placement to protect against uneven wrapping. Next off, the Machine's electric links must be taken a look at for wear or damages, as defective electrical wiring can lead to functional failings - stretch wrap machine repair near me. Additionally, the belts and rollers must be examined for any kind of signs of damage, ensuring smooth movement. Verify that safety guards are in location and operating properly. By adhering to this everyday list, operators can determine potential problems early, reducing downtime and prolonging the life of the stretch Wrap Machine. Regular inspections ultimately add to efficient and dependable procedures

Lubrication Schedule Value

Frequently neglected, a well-structured lubrication routine plays a critical function in the maintenance of stretch Wrap devices. On a regular basis using the ideal lubricants to essential components minimizes rubbing, decreases wear, and enhances general capability. This positive strategy not only prolongs the lifespan of the devices yet additionally ensures regular performance, lowering the possibility of unanticipated break downs. Operators should adhere to the supplier's recommendations pertaining to lubrication intervals and sorts of lubes to use. Monitoring lubrication degrees and observing any changes in Machine procedure can provide useful understandings right into prospective problems. Eventually, a thorough lubrication timetable is important for keeping efficiency and dependability in stretch Wrap devices, contributing significantly to functional productivity and cost-effectiveness.

Component Substitute Guidelines

Troubleshooting Tips for Quick Fixes

When experiencing problems with a stretch Wrap Machine, speedy troubleshooting can considerably lower downtime and boost performance. Operators needs to initially speak with the Machine's manual for particular error codes or indicators. A common issue is improper tension; adjusting the tension setups can typically settle irregular covering. Checking for blockages or making sure the film is filled effectively is essential.Another regular issue is the Machine delaying if the film is not feeding properly. In this case, inspecting the electric links and fuses may reveal issues. Frequently lubing moving components can avoid mechanical failures, while guaranteeing that all components are aligned will boost performance. In addition, monitoring the Machine for unusual noises can offer very early warnings of possible breakdowns. Implementing these troubleshooting steps can result in quick repair work, lessening disturbances in operations and maintaining reliable operations.

When to Look For Specialist Aid

Recognizing when to look for specialist assistance for a stretch Wrap Machine is essential for keeping functional performance. Indications such as uncommon sounds or vibrations, frequent movie damage, and inconsistent Wrap stress can suggest underlying issues that call for experienced focus. Resolving these troubles promptly can avoid more damages and ensure the Machine operates efficiently.

Uncommon Noises or Resonances

Uncommon noises or resonances from a stretch Wrap Machine can show underlying issues that may jeopardize its performance. These abnormalities commonly recommend imbalance, worn components, or not enough lubrication, every one of which can lead to more substantial problems if left unaddressed. Operators should monitor the Machine carefully for any modifications in audio or resonance patterns, as this can provide important understanding into its condition. If the sounds are persistent or the vibrations are too much, it is recommended to look for specialist aid. Disregarding these indication might result in expensive repair services and downtime. Regular assessment and maintenance can minimize risks, but when doubtful, speaking with an expert ensures the Machine runs effectively and securely.

Constant Movie Breakage

Frequent movie breakage in a stretch Wrap Machine can signify underlying problems that require immediate focus. Operators ought to first examine the movie high quality, guaranteeing it fulfills the Machine's specs. Worn or poorly installed movie rollers might likewise contribute to the problem, leading to enhanced tension and film anxiety. Furthermore, misalignment of the Machine elements can exacerbate damage, indicating the demand for adjustment or replacement of components. If these fundamental checks do not settle the problem, it may be time to speak with a professional technician. stretch wrap machine repair near me. Specialist treatment can determine much more complex problems, such as motor breakdowns or software concerns, making certain the Machine operates efficiently and effectively. Timely professional aid official source can protect against more damage and pricey fixings

Irregular Wrap Stress

Inconsistent Wrap tension can cause inappropriate load security and enhanced material waste, making it a considerable worry for stretch Wrap Machine drivers. This issue commonly emerges from equipment malfunction, such as damaged components or improper calibration. Operators should monitor tension closely, as changing levels can compromise the integrity of wrapped lots, causing damages throughout transportation or storage. If adjustments to the Machine settings do not fix the concern, it might indicate deeper mechanical issues. Seeking professional assistance is suggested when there are relentless variances, as knowledgeable service technicians read what he said can identify and repair underlying concerns that may not be quickly apparent. Timely treatment can not just restore perfect efficiency yet likewise extend the life of the stretch Wrap Machine.

Finest Practices for Preventing Devices Failings

While routine upkeep is important for ensuring the long life of stretch Wrap machines, applying best techniques for preventing tools failures can considerably boost their integrity. First, operators need to follow a stringent routine for routine inspections, focusing on key parts such as equipments, belts, and motors. Keeping track of performance metrics, consisting of Wrap stress and rate, can assist determine prospective problems before they escalate.Additionally, making certain that the Machine is used within its specified capacity can reduce excessive stress on components. Training personnel on proper operation methods is important, as improper use can bring about early wear or damage.Regularly cleansing the Machine to get rid of particles and dirt can likewise enhance performance. Finally, maintaining a well-documented upkeep log enables for better monitoring of repair work and can help in identifying recurring issues. By following these finest methods, companies can considerably reduce the danger of unforeseen equipment failures.

Regularly Asked Questions

Exactly how Typically Should I Replace Stretch Wrap Movie?

The frequency of stretch Wrap film substitute depends upon use, environmental variables, and film top quality. Usually, businesses evaluate movie honesty on a regular basis, changing it when signs of wear or damage become noticeable to guarantee peak performance.

Can I Utilize Non-Standard Movie With My Stretch Wrap Machine?

Using non-standard movie with a stretch Wrap Machine may cause compatibility concerns, affecting efficiency and possibly causing damages (stretch wrap machine repair near me). It is a good idea to get in touch with the Machine's requirements and manufacturer guidelines prior to trying to use alternative films

What Are the Indicators of Put On in Stretch Wrap Machine Components?

Indications of wear in stretch Wrap Machine components include unusual sounds, irregular wrapping stress, noticeable damages to components, getting too hot, and raised downtime. Regular assessments and upkeep can assist recognize these concerns before they escalate into significant troubles.

Exist Particular Cleaning Products Recommended for Maintenance?

The concern of suggested cleansing items for upkeep often arises. Specialized degreasers and non-corrosive options are commonly suggested, making sure effective cleansing without harming sensitive elements, as a result extending the tools's life-span and keeping perfect efficiency.

Exactly How Does Humidity Impact Stretch Wrap Efficiency?

Humidity considerably affects stretch Wrap efficiency, affecting its attachment and tension. High humidity can cause decreased stick residential or commercial properties, while reduced moisture may create brittleness, eventually endangering the honesty and effectiveness great site of the covered items. In any type of product packaging operation, problems with stretch Wrap makers can emerge in spite of a strong understanding of their elements. Regular movie breakage in a stretch Wrap Machine can signify underlying problems that need instant focus. Inconsistent Wrap stress can lead to improper tons security and boosted product waste, making it a considerable worry for stretch Wrap Machine drivers. Using non-standard film with a stretch Wrap Machine may lead to compatibility problems, impacting efficiency and possibly triggering damages. Indications of wear in stretch Wrap Machine elements consist of uncommon sounds, irregular wrapping tension, noticeable damages to components, getting too hot, and raised downtime.

Comments on “stretch wrap machine repair near me: Tips for Avoiding Electrical Short Circuits from Disrupting Production”